Henan mine quality excellence Baosteel A seized successfully passed

[ times:2016-11-10 hits: ]

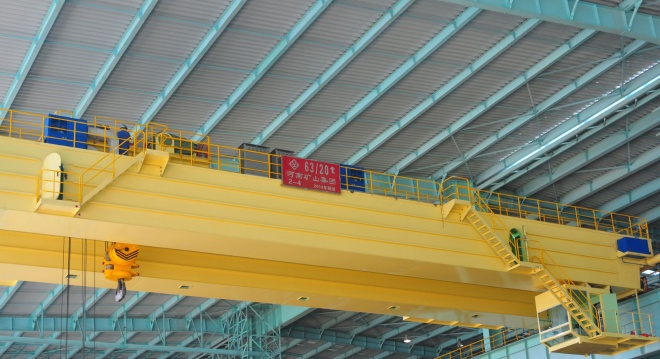

Recently, the system of our company Baosteel Group of second batches of crane products passed the A examination again.

In order to ensure the quality of manufacturing equipment, our company set up a special project of Baosteel Group, the implementation of strict quality management, supervision and control of the manufacturing process in each crane after the production, are commissioned by Baosteel Group third party inspection agencies strict quality inspection of our company crane products, first detection group crane self check the report, produced by our company material report and inspection reports and other information, according to the requirements of the contract to A. I outline issued by the company as the basis, for each crane factory inspection, inspection method is divided into: A examination preparation equipment inspection, static checking, dynamic inspection equipment, structure and size of test equipment etc.. According to the technical agreement, drawing data and the contents of the inspection outline, the factory will be carried out without load test.

After the first batch of products were detected by A to Baosteel Group, after the actual operation, the equipment is in good condition, the product performance has been highly evaluated by the user. Baosteel Group on the effectiveness of quality control in our company to give high praise.

With this opportunity, Baosteel Group decided to 1550mm Cold Rolling Workshop 33 cranes all by my company's system. 16 cranes used Gray bus positioning technology, automatic unmanned operation. This technology is the first case in the country.

last:The company held a grand banquet of "three eight women's D

next:Henan mining group, the fourth Mid Autumn Festival Culture Festival held a grand